The 5 Steps To Making A Pewter Tankard

Firstly, what is Pewter?

Pewter is a metal alloy with its main component being tin. Ancient Pewter consisted of around 70% tin and 30% lead, however, lead was outlawed in the 70s, due to its associated health risks – but our mix has never included it, going back to the 1940s for us and the 1760s for Sheffield in general. The alloy that we use for all our products is based on a recipe of 92% tin, 6% antimony and 2% copper – no lead!

Pewter has many advantageous properties that make it suitable for being made into Tankards, Trinkets, Trophies and much more, including…

- Low melting point (170 – 230 degrees Celsius)

- Soft metal (due to its tin and copper content)

- Malleable (able to be reshaped by hammering or pressing, without cracking)

- Ductile (can be stretched into a thin wire without breaking)

- Ability to alter the finish of the pewter depending on the production methods used

- Safe to drink/eat from

These interesting properties mean that pewter can be worked using relatively simple equipment and methods, but only when combined with a highly skilled Pewtersmith can they create something very special, such as a Pewter Tankard!

5 Steps to Making a Pewter Tankard

Before pewter is made into items such as tankards, you can find it as ingots, sheets/circles and pellets/shot. Depending on what product you intend to make with it, determines which pewter form would be most suitable for your project. Usually, a combination of the above is required e.g. a pewter circle for a tankard’s body and an ingot to cast into the handle.

Step 1. Drafting – Firstly, a circle of Pewter is drawn out over a forming block by a spinner. A ‘Section Chuck’ is required to make the ‘tulip’ shape of the tankard body. This whole process redistributes the metal around the forming block, changing the thickness of the pewter and forming a ‘lip’ at the top of the tankard. The ‘foot’ of the tankard is formed from another circle of pewter, which is also drafted over the forming block. The centre of the foot is then cut out, so that the tankard body can be attached later.

A Pewtersmith shaping pewter over a forming block.

Step 2. Slush Casting – This process is then used to cast the handle of the tankard. Molten pewter is poured into a cold metal mould and solidifies – the excess, still-molten pewter is then poured out, making the handle hollow. Where the pewter has been poured in, there will be what is known as a ‘gate’, which is not part of the handle and is trimmed off using a band saw. The mould leaves a ‘Mould Line’, which is removed by a process called ‘linishing’ – this is when the metal is sanded down to create a smooth surface to get rid of the line. The handle is then shaped for the specific tankard it is to be attached to.

Pouring molten pewter into the cold metal mould.

Step 3. Buffing – The tankard then undergoes buffing to clean and smooth the surface. This is done by applying pumice and rapeseed oil to the tankard and using a tough stitched mop grinder. The smooth surface will make it easier for the metalsmiths to assemble the product and, eventually, undertake the polishing process.

Buffing the pewter using pumice and rapeseed oil.

Step 4. Soldering – The foot of the tankard is attached to the body using a process called soldering. In this case, heat is applied to the tankard itself (as opposed to the soldering wire) and the soldering wire is melted onto it. This creates a clean, neat and strong seal between the tankard body and foot. The handle is also attached in the same way.

Soldering the foot of the tankard to the body.

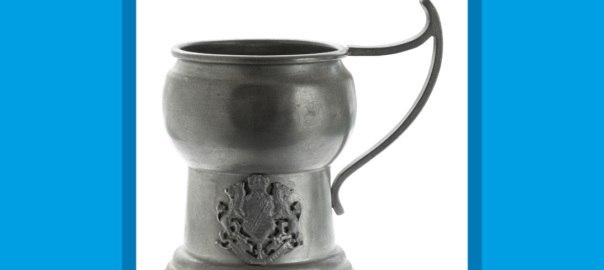

Step 5. Polishing – The tankards are washed and dried on a drying table. The tankards then undergo a final polish. On some of our tankards, two different finishes are applied; the inside of the tankard is polished to create a ‘satine’ (matt) finish, which is done using the mop grinder. The outside of the tankard is highly polished using a rouge compound applied to a soft cotton mop to achieve the very high sheen and silver-like finish that you see on all of our pewter tankards, such as the one below…

Polishing the tankards.

Our Touchmarks

Our Touchmark is pressed into most of our pewter products and consists of 5 symbols, each with a different meaning. These represent our authenticity, quality and craftsmanship.

ARW – The initials of our founder, Arthur Richard Wentworth, who founded the company in 1949.

92 – The minimum percentage of tin, the fourth most precious metal.

EPU – Our European Pewter Union membership.

ABPC – The Association of British Pewter Craftsmen mark.

Two sheaves of arrows – part of the City of Sheffield’s coat of arms.

Decorative techniques – embossing, engraving and hammering

Decorative techniques, such as embossing, engraving and hammering, can be applied to the pewter to give it a unique finish. We offer a range of pewter tankards and pewter gifts, and each of them are made unique by the decoration – for example, we have birthday, anniversary, wedding and retirement gifts, thoughtfully themed to match the occasion. We can also engrave your own logo/crest/coat of arms/design or your own message in your choice of font.

Since all of our pewtersmithing is done here at our factory in Sheffield, this means we can also create special commission designs for events or unique corporate designs for your business.

Engraving a tankard using an engraving machine.

Variety of Handle Designs and Optional Extras

We pride ourselves on incorporating unique designs into our pewter gifts, which, for example, is why we have such a wide range of handles available to choose from for our pewter tankards. Our handles are moulded from molten pewter, meaning we really can achieve anything – from lions to foxes, keys to golf clubs and the more simply shaped handles; there really is something for everyone.

Our popular Teddy Bear Handle Baby Mug.

We also offer a few ‘optional extras’. For flasks, we offer a ‘Captive Top’ (which is an attached lid on your pewter flask) and a pewter funnel. In terms of our pewter tankards, we offer Lidded Tankards and Glass Base Tankards.

Pewter is a fascinating metal and so we hope this blog post has encouraged you to have a look at our wide range of products or perhaps even have a go at some Pewtersmithing yourself!

Thanks for your blog, nice to read. Do not stop.